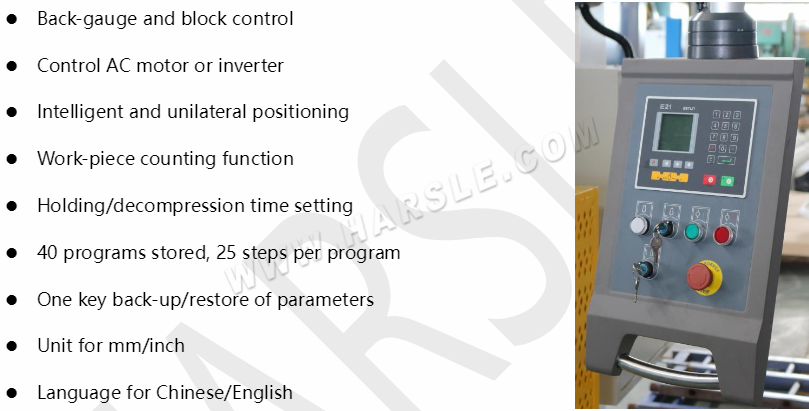

frequency hydraulic control technology, with more stable, and more reliable operation. Therefore, most users perform the first bending after the first hour of our training on using the machine. Hydraulic synchronization control and Estun NC programmable logic. Please comply with the following instructions to avoid noise generated by signal. The device is effortless to use, but additionally, it includes a user-friendly and logical menu and 24 setting buttons. No patent liability is assumed with respect to the use of the. Moreover, you can be sure that the device makes all components according to the same parameters as the Estun E21 controller includes saving up to 40 programs, 25 steps each.

In addition to saving money due to the lower producing cost, you also save time to transport the goods. If your company continually uses subcontractors’ services, it is certainly worth thinking about buying a press brake.

#Estun e21 operation manual install

The perfect fit for companies with a well-defined and reasonably stable production process. E21 Installation Manual Preface Target reader This manual guides the following operators to install, configure and maintain the E21 press break numerical control device: Machine tool operators Installation and maintenance personnel Range of application Installation and maintenance personnel can install and operate this device properly by referring to this manual. Press brakes, including Estun E21 controller, are intended mainly for making simple and repetitive elements. Thanks to the components applied to them, various models of press brakes allow obtaining different work efficiency. There is no versatile solution for each individual, though the first question you should ask yourself before purchasing an NC-controlled press brake is: What components are we going to make, the batches, and how complex will they be? Integrated hydraulic system (Bosch Rexroth. In contrast to CNC controllers, it does not perform calculations for the user however, it contains several improvements, such as saving programs. Hydraulic synchronous control and Estun NC programmable logic controller ensure accurate repeatability and ease use. In other words, it transfers all the setting options from classic “manual” press brakes to a digital device.

This controller belongs to the group of so-called numerical controllers. Never touch any rotating motor parts while the motor is running. Although its capabilities are inferior to advanced CNC controllers, it is sufficient to produce repeatable and not complicated components. Read this manual thoroughly before checking products on delivery, storage and transportation, installation, wiring, operation and inspection, and disposal of the AC servodrive. The device operates with numerical press brakes. FREQUENCY TRANSFORMER is not the standard components, optional.Estun E21 is an easy-to-use controller manufactured by Estun Automation. – ESTUN E21 will work better accompany with FREQUENCY TRANSFORMER. – ESTUN E21can control X axis working into position accurately – ESTUN is jointed company by HOLLAND DELEM AND CHINA ESTUN – ESTUN E21 is a simple NC control system designed to replace ESTUN E200 with lower price. to add or delete part or all of the manual content without ESTUN s consent. Also, high rigidity and tenacity machine body frame ensures machine longer quality working age and high-accuracy. 3 Preface This manual describes operation of E21 numerical control device. Torsion bar synchronization design brings compact machine structure and high cost-performance.Įasy adjustment makes WC67Y very popular for common bending working needs. It is the perfect machine for common bending needs and high cost-performance.

WC67Y is torsion bar synchronization NC press brake, compact in structure, easy in operation adjustment, stable in usage and high precision synchronization.

0 kommentar(er)

0 kommentar(er)